Case Studies

Smart Camera Helps the Wheels Go 'Round and 'Round

Machine vision-based assembly system fits and mounts wheels onto cars in continuous operation

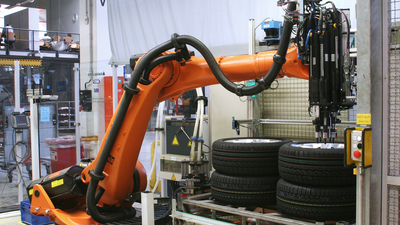

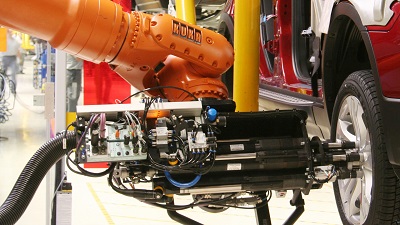

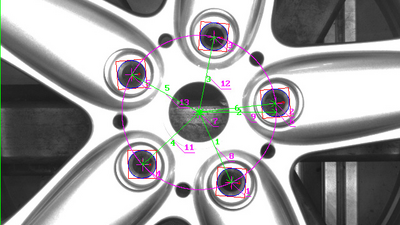

Two six-axis Kuka industrial robots—one located on each side of a car body—gather wheel bolts and rims from their supply stations and screw them onto the car. The robots are synchronized with the conveyor and follow the car’s movement during assembly. Attached to each robot is specialized lighting with polarized and infrared filters. A Matrox Iris GT smart camera is also attached to each robot. The smart camera locates the rim’s center point and calculates its position (x, y), rotation (Rz) of the bolt circle, and distance to the camera (z) in calibrated coordinates. Before these coordinates are given to the robot, the smart camera checks to see whether the rim design that it has located matches the rim that is expected to be given by the PLC. This last test prevents the wrong rim design from being mounted on the vehicle. Thirteen different wheel combinations—seven rim designs and four types of lacquer (white, silver, anthracite, and black)—are identified. The entire automated wheel assembly process has a cycle time of only 54 seconds.

Smart camera-based image processing

Some challenges

IBG is a longtime user of Matrox smart camera technology. Kai Kluwe, Head of Software Development Machine Vision/Measurement at IBG, explains, "Our experience with Matrox Iris smart cameras and its software has been very positive—we’ve deployed successful projects in the past using Design Assistant’s efficient edge-based search tools." IBG is also extremely pleased with the level of technical support that was offered to them. In addition to the skilled local assistance that they received from Rauscher GmbH, Matrox Imaging's master distributor in Germany, IBG took advantage of expertise available from Matrox Imaging's Montreal-based, Vision Squad, a team of algorithm gurus who help customers assess application feasibility and determine how to best use Matrox software to solve application challenges. In this case, these challenges included IBG’s need to handle different design and color combinations along with overlapping rims resulting from their placement on the skid. A clever algorithm based on the Geometric Model Finder and Metrology steps was required to only use the indicative features belonging to the rim in the foreground while discarding those that belong to rims behind it. Other challenges included having different settings for image acquisition and Model Finder steps on each side of the assembly line and for each rim type, in addition to ensuring reliable depth measurement with a 2D camera. “The Vision Squad provided an alternate and optimized method of using the Metrology tool so that we were able to improve overall robustness,” explains Kluwe.

The Matrox Iris GT smart camera locates the rim's center point and calculates its position (x, y), rotation (Rz) of the bolt circle, and distance to the camera (z) in calibrated coordinates. Before these coordinates are given to the robot, the smart camera checks to see whether the rim design that it has located matches the expected rim type. Source: IBG Automation GmbH.

IBG Automation is part of the Goeke Technology Group. For the past 30 years, Goeke has been developing innovative robot and automation systems that meet clients' specific requirements. Industries served include automotive, pharmaceutical/chemical, food, aerospace, electronics, energy, consumer goods, and telecommunications. The company has more than 200 employees at facilities in Germany and the USA. Source: IBG Automation GmbH.

Deployment

For more information contact Media Relations.