Case Studies

Decoration Goes Digital

Matrox Imaging smart camera powers vision system of award-winning food printer

Entrepreneurial spirit

Configurable printing system

Overnight mode

The baths and curtain processes especially require an extensive cleaning procedure when switching between products—for example, when switching to a different color frosting or switching from milk chocolate to dark chocolate. Because the FoodJet printer is a closed system, the switch can be done by connecting the reservoir with the new product and flushing the system before connecting the return flow to the reservoir. "A closed system prevents mixing of product ingredients or environmental contamination to ensure the best possible hygiene and food safety," says De Grood. "One of our customers managed to reduce the time it took him to switch between decoration fluids by 90%, as he no longer needed to spend four or five hours cleaning his machine. The transition time with the FoodJet printer now only takes several minutes."

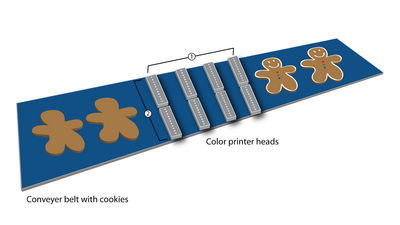

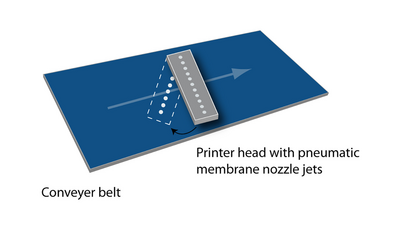

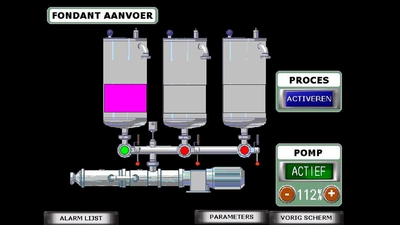

Machine vision

The printer's vision system uses a Matrox Iris GT smart camera (1). Additional reservoirs contain liquid that can be dispensed within minutes if a switch is needed (2). The HMI provides the operator with information on choice of product, pressure and shutter times of valves (3). Printing heads (4). Source: De Grood Innovations.

A Future Beyond Food

For more information contact Media Relations.