Case Studies

Case Packing Made Better with Machine Vision

Beverage manufacturer uses smart camera-based packaging inspection system to eliminate orientation and count errors

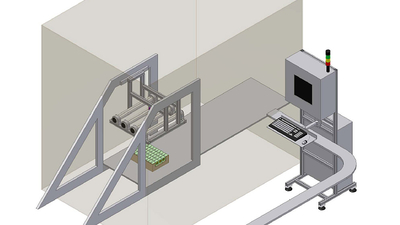

A global soft drink and beverage manufacturer was experiencing difficulties with case packing orientation and count errors that were resulting in customer complaints and machine downtime because of jams. Acquire Automation, an automation solutions and services provider headquartered in Fishers (Indianapolis), IN, was hired to develop a complete packaging inspection system to solve these problems. The solution was integrated within an existing case packer and uses machine vision to count and verify the orientation of 40- and 50-count cases of shrink-wrapped and non-shrink-wrapped juice boxes.

On the line

The inspection line includes a machine vision system, a Programmable Logic Controller (PLC)-based feedback control system, an intuitive Human Machine Interface (HMI), and an imaging frame, which ensures that the camera is protected and that the product is properly illuminated. The HMI and the imaging frame are both designed by Acquire Automation. The vision system uses a Matrox Iris GT smart camera for imaging and tool algorithm execution. Other machine vision components include a breakout board, imaging lens, 120 V high-frequency fluorescent lights, and cabling.

Smart camera-based vision system

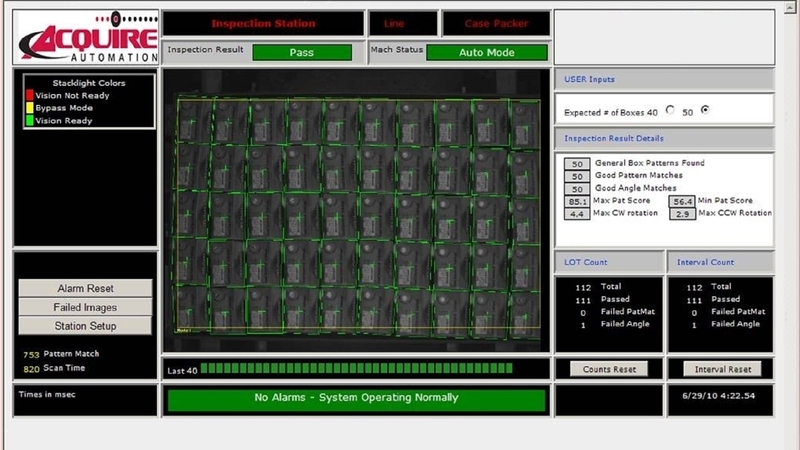

The inspection application was developed using Matrox Design Assistant, an integrated development environment (IDE) bundled with Iris GT smart camera. The IDE enables users to create machine vision applications by constructing flowcharts instead of coding programs or scripts. Once development is completed, the project (or flowchart) is uploaded and stored locally on the camera. The project is then deployed on the Iris GT and monitored from the easy-to-use web-based Human Machine Interface (HMI) running on a PC. An operator can interact and adjust the system without connecting to a control system or performing complicated system programming.

Several Design Assistant tool or flowchart steps are used in the inspection application. The main tool, pattern matching, correctly identifies the presence and orientation of the juice boxes. Additional tools—fixturing, intensity checker, and image processing—are required to correctly position and set threshold tolerances for the pattern matching tool.

Acquire designed the HMI so that it is extremely simple for operators to view counts, set tolerances, store previous images, and adjust camera settings. The HMI also provides login access control to prevent unauthorized personnel from altering the system and includes detailed product counters for data collection and trend estimation. The system automatically saves failed inspection images for follow-up analysis.

Why a Matrox Iris smart camera?

Several factors resulted in the beverage manufacturer selecting the Matrox Iris GT for the case packer’s vision system. John Duffin, Vice President at Acquire, explains, “The Iris GT’s small form factor played a role, but more importantly, it was the size and expertise of the Matrox organization—including its applications support team—coupled with Acquire’s solutions team, which made the end customer confident that the Matrox smart camera was a robust and supported solution.”

In addition to the valuable assistance that they received from North Coast Technical Sales, Matrox Imaging's master distributor in the U.S. midwest, Acquire relied extensively upon the technical support provided by Matrox’s Vision Squad, a team of algorithm gurus who help customers assess application feasibility and determine how to best use Matrox processing/analysis tools to arrive at an optimal solution. Arnaud Lina, Image Processing Manager at Matrox Imaging, oversees the team and elaborates, “As a supplier of machine vision components, we know that a gap frequently exists between a product’s functionality and the expertise that a customer must have to best integrate that product into his own application. Machine vision is not and will never be a perfect science, so the Vision Squad’s goal is to be the bridge that lets us transfer our experience and knowledge to clients in the most efficient and direct manner.”

John Duffin comments, “We used the Vision Squad’s expertise on multiple occasions to consult and review project development and execution optimization. The integrator support team assisted with writing touch screen drivers, developing custom steps for focus adjustments, and optimizing flowcharts for speed and HMI interaction. This support helped us deploy a solution under tight budget and time constraints. It’s great to have a responsive team to assist you in deploying solutions as quickly and effectively as possible.”

Installation

One of main challenges faced by Acquire during development was that—although multiple SKUs were running on the line—the customer wanted little operator interaction. As a result, the vision flowchart had to be flexible enough to handle all of these changes. John Duffin explains, “We decided to take different features of the box, including color, size, location, etc., to help determine what general SKU is running, and then base our vision decisions (tolerances and patterns) on the general results.” Another challenge was to consistently light the product for all the different SKUs, as well as the bundling film that may or may not be present on the juice boxes.

Conclusion

The solution has received extremely positive feedback from the customer since it has resolved their packing orientation and count errors. The system has been able to detect the following errors: skewed, missing, crushed, fallen, turned, or extra boxes; missing, upside-down, or reversed bundles of shrink-wrapped juice boxes; damaged J-cards (labels that go on the shrink-wrapped case of juice boxes); skewed trays; and boxes with tabs up. The vision system not only works to identify these product issues, but it also helps to quickly identify a process issue and, often, the root cause of the failure. This results in countless savings of man hours and significantly reduces customer recalls and complaints. John Duffin elaborates, “Without vision, the majority of these issues would be identified via quality sampling, if at all. At that point, corrections become extremely labor intensive, requiring manual inspection of tens to hundreds of thousands of products.”

Looking to the future

From the time that the case packing inspection system deployed in October 2010, its success has led to the implementation of an Iris GT-based label inspection system on a second packaging line. The customer is planning to introduce the inspection system to several other juice box lines and similar beverage packaging operations within the facility.

For more information contact Media Relations.