Case Studies

Brake Disk Manufacturer Refines Quality Assessment with Vision System

Matrox Design Assistant X vision software optimizes quality assurance verification with highly efficient algorithms

“With human inspectors, it is natural that product samples, especially those close to the limit between good and bad, will be assessed differently by different operators. The likelihood of these differences increases after humans have worked a few hours and are tired,” notes Pistilli, “but with a vision system, in addition to the enhanced quality control, the inspections are repeatable 24 hours a day and the machines perform faster than any operator could.”

With the new Matrox Imaging-based vision system, quality control inspection occurs faster and with greater accuracy and repeatability than with the prior manual inspection process. The result? Fewer non-optimal brake disks passing through the inspection process.

Perfection under pressure

Every camera has a different shooting position; images are captured while the disks pass through the inspection tunnel on the moving production line. As the system comprises multiple cameras, Pistilli notes, “Matrox Design Assistant X is the right tool because of its ability to spread the load over the available CPU cores, and the possibility to synchronize all elements of the systems with ease. Moreover, this flowchart-based software allowed our developers to focus more on achieving our desired accuracy and performance, and the algorithm logic, instead of worrying about coding.”

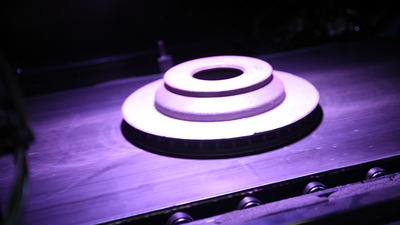

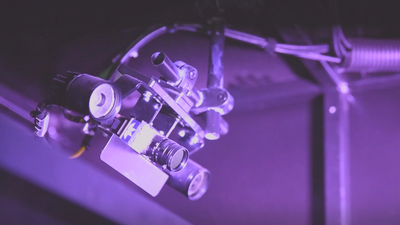

One of the nine cameras integrated into the vision system. Image sensors are more responsive to lower wavelengths or blue-purple light, which accounts for the unique purple tone of the image. Working with purple light best brought out the defects, allowing the MOSAIC team to shorten the exposure and thus speed up the vision inspection.

Smoothing the edges

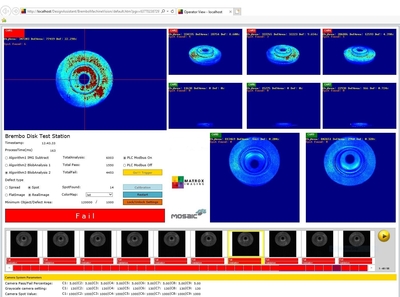

The Operator View created within Matrox Design Assistant X streamlines management of recipes and parameters, with a user-friendly touch-screen interface. The filmstrip format makes it easy to retrieve previously acquired images and datasets; a dataset is generated for each analysis for quality-control investigation purposes.

Conclusion

For more information contact Media Relations.